As a leading German manufacturer, AWP manufactures pressure relief safety valves for the refrigeration and cooling processes essential for industrial activities such as cold storage, shipping, chemical processing, cement manufacture and pharmaceuticals. These and many more applications are all highly specialized industries and customer specific solutions.

AWP valves are suitable for use with natural refrigerants, non-corrosive gases and liquids and cooling brine.

The range of pressure safety relief valves offered by AWP includes a selection of both standard and specialised configurations in form, materials and function.

Safety relief valves may be either back-pressure dependent or made independent through a specialised metal below which ensures backpressure sealing.

All safety relief valve configurations may be additionally protected by the installation of a rupture bursting disk to avoid contamination or corrosion of the safety relief valve inlet and seat from aggressive mediums and other impurities

Design

angle type

Material

steel or stainless steel

Nominal Size

DN 10/10 up to 65/100

Nominal Pressure Level

PS 25, PS 40, PS 63

Temperature Range

A: – 60 °C to +180 °C

B: – 50 °C to +110 °C

Connection

flanged ends DIN, ANSI

but welding ends, screwed ends

AWP is certified to manufacture safety pressure relief valves according to the standards organizations and certifying bodies as listed.

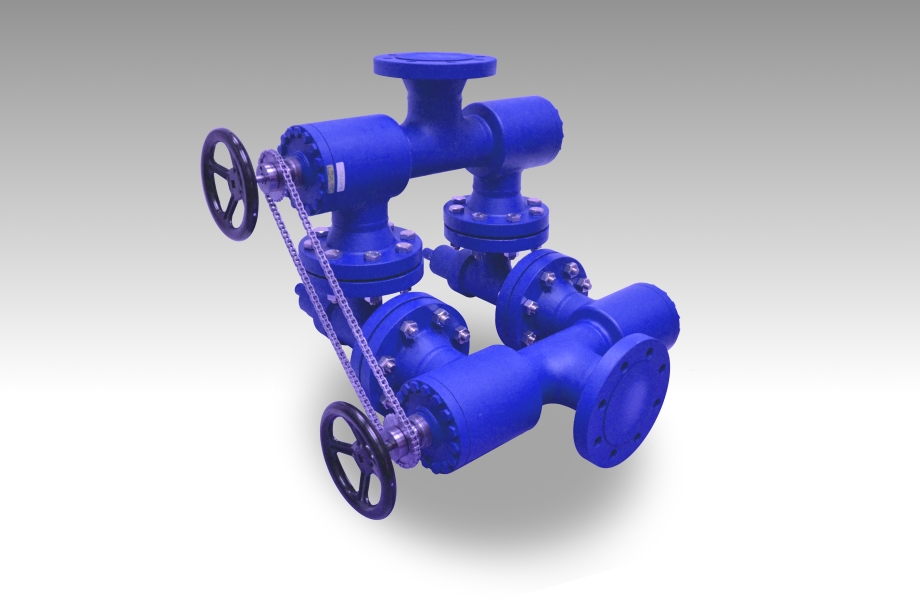

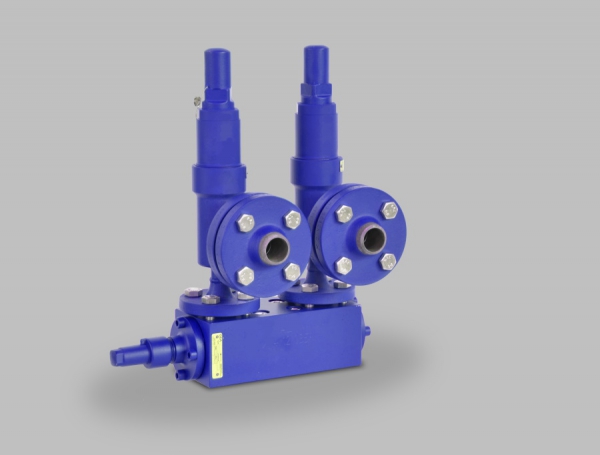

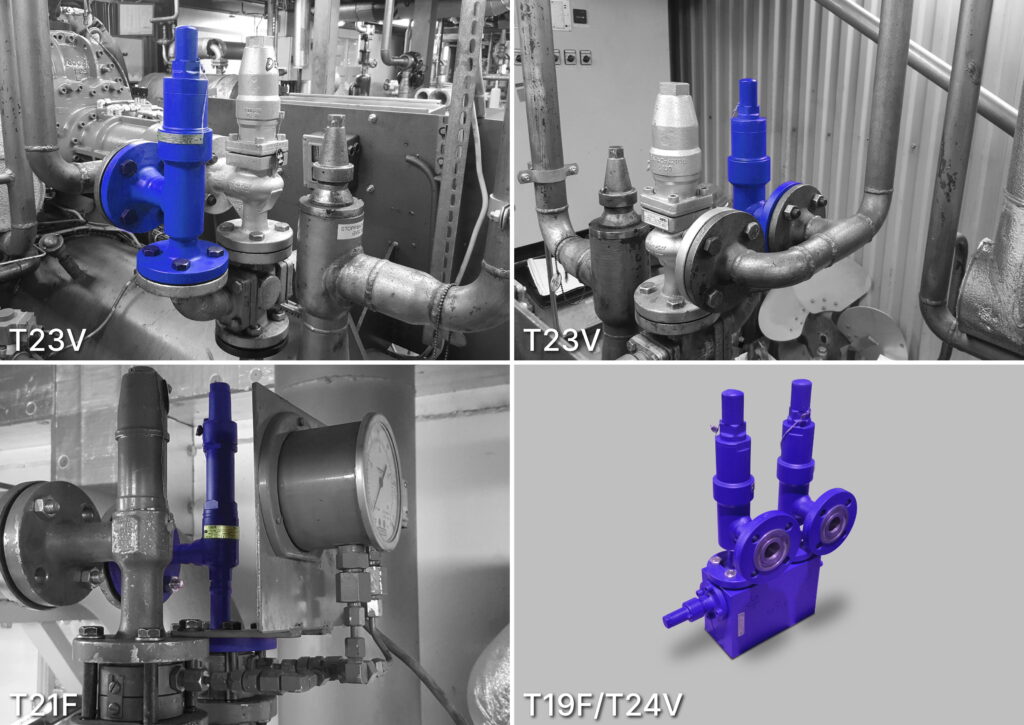

The safety valves described above are also available as double pressure relief valve combinations via a 3-way-valve. The object of a pressure relief valve combination is to enable the exchange of PRV’s without shutting down the compressor or the plant.

A dual safety valve with a 3-way valve on the inlet and outlet may also be supplied with the additional security of a chain driven actuation between the two 3-way valves. This is done to ensure that through the possibility of operator error, a circulation system may not be accidentally entirely shut down, this is for example a safety regulation commonly found in the chemical industry.

As with the single safety relief valve installations employing a rupture bursting disc, the double safety valve combinations may also be protected by installing this useful device directly before the inlet connection of the pressure relief valves. The bursting disc prevents the operating medium from having contact with the PRV’s inlet and so avoids contamination or corrosion of the safety valves.

The inlet and outlet diameters for the pressure relief valves are from DN 10 (3/8’’inch) to DN100 (4’’ inch). The performance ratings for flow – pressure drop – and many more information you will find by using our selection software ValveCalc and our operation instructions.

The set pressure ranges for the safety relief valves begin at 4 bar and have a maximum level at 63 bar. The lowest working temperature is at -60 C° (- 76 F°) and the highest operating temperature is 180 C° (356 F°).

For the manufacture of safety relief valves and for the pressure relief valve combinations we offer housing bodies from a range of various materials. These include carbon steel (CS), stainless steel (SS), low temperature steel (LTCS). The choice of valve bodies offered may be of a welded tube fabrication type, a casting or a forging.

The connections include all flange types, welded joints and threaded connections. The pressure relief valve stem sealing system employs neoprene or PTFE seals.

For our safety relief valves and pressure relief valve combinations, the working mediums include all relevant refrigerants as listed:

AMMONIA, CO2, Helium, R22, R404A, R507, R134a, Propane, Propylene, Butane, non-corrosive liquids and gases and brine based on glycol

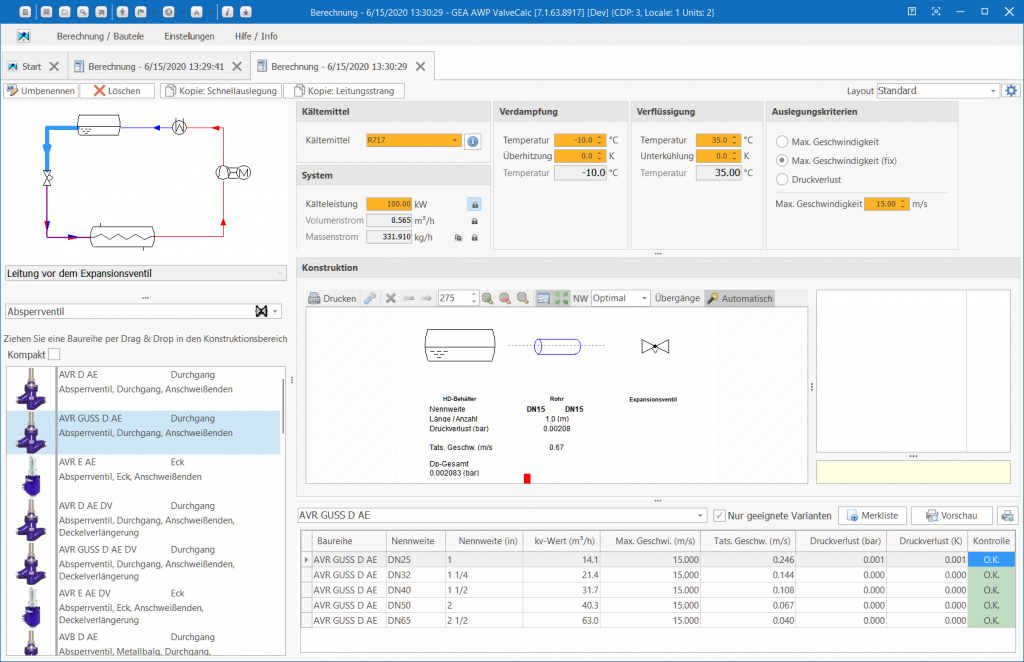

The ValveCalc calculation program assists designers, engineers and plant maintenance personnel with the selection and performance dimensioning of pressure relief valves for installations. The software meets the current requirements for international standards and industries.

By entering the operating conditions and technical data, users of the ValveCalc software follow a step-by-step guide to assist in the choice of possible valve types and sizes. ValveCalc may also be utilised to determine the configuration of a complete section of a system with several various design models.

The new Version, which is provided free of charge on request, takes into account the current international standards in industrial refrigeration and includes the latest standard for safety relief valves according to EN 13136:2013. With this, the pressure loss calculations of the supply and discharge lines of the safety valves and based on the true discharge volume and not the theoretical required volume. The maximum allowable pressure of the safety valves is now automatically calculated and displayed. The extensive database of refrigerant data has been expanded particularly to include the range of superheated refrigerants.

AWP offers replacement safety relief valves to suit the customers’ existing installation dimensions and configured accordingly to meet the customers performance requirements. So without any additional effort on site is a replacement from a Herl pressure relief valve (T21F, T23V etc.) easily possible.

AWP is proficient in the development of individual solutions custom designed to meet specialised requests. In cooperation with the customer, we were able to develop many unique selling points in worldwide projects for numerous industries and international markets.

Our knowledge and experience in manufacturing and developing complex valves and components enables us to provide perfectly designed solutions. This innovative support of customers results in potentials and synergies that should prove advantageous to all parties.

Don’t hesitate to contact us as we take great pride in our customer support facilities.

Nehir Memet

Tel: +49 3984 855967

E-mail: nehir.memet@gea.com

As part of the global operating GEA group, GEA AWP is the specialist for the development and manufacture of valves and components used in industrial heating and refrigeration plants and machinery. The company is based in the town of Prenzlau, located near Berlin and employs about 100 employees.

GEA AWP GmbH

Armaturenstr. 2

17291 Prenzlau

Germany