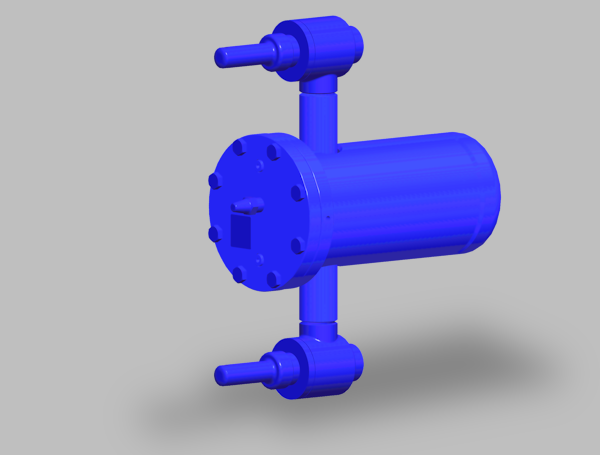

Home > Products > Filters / Strainers > HSX High Pressure Float Valve

HSX high pressure float valves have a shut-off valve welded onto the inlet as well as onto the outlet, as well as a vacuum nozzle and an externally operated transport lock / manual adjustment that can be operated from the outside. In addition, service valves for emptying and discharging non-condensable gases can be installed via two G¼” threaded connections.

Depending on the designed throttle opening, the refrigerant is released from the high pressure to the low pressure side of the refrigeration system. The built-in N-ball is suitable for NH3 and CO2 applications.

Release the transport lock before use; the mechanical design works without electricity/electrical voltage and does not require regular maintenance cycles.

When ordering, please specify the throttle opening (-X, -H, -M, -L), the refrigerant and the application (Qo, to ,tc).

Material

steel

Nominal Size

DN 50 and DN 80

Nominal Pressure Level

PS 40

Temperature Range for Standard Valves

-60 °C to +75 °C

Connections

butt welding ends as per DIN and ANSI

integrated manual adjustment / transport lock

GEA AWP GmbH

Armaturenstr. 2

17291 Prenzlau

Germany

Phone: +49 3984 8559-0

Fax: +49 3984 8559-18

As part of the global operating GEA group, GEA AWP is the specialist for the development and manufacture of valves and components used in industrial heating and refrigeration plants and machinery. The company is based in the town of Prenzlau, located near Berlin and employs about 100 employees.

GEA AWP GmbH

Armaturenstr. 2

17291 Prenzlau

Germany