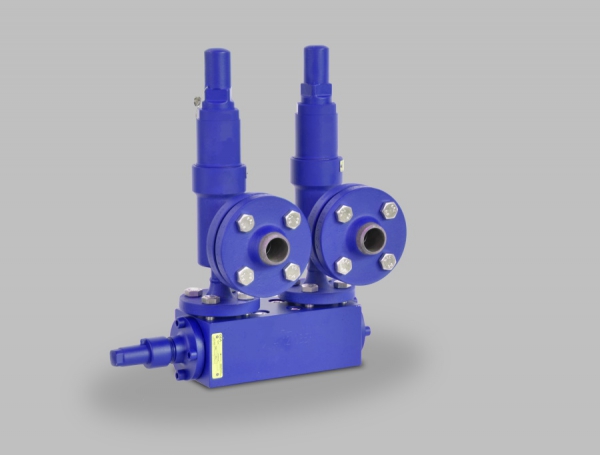

Home > Products > Dual Safety Valve Combinations > WVR AL SVA / SVU Dual Safety Valves

aluminum (3-way valve)

steel or stainless steel (safety valves)

Nominal Size

PS 25, PS 40, PS 63

Temperature Range for Standard Valves

WVR AL-SVAA / WVR AL-SVUA: -60 °C to +120 °C

WVR AL-SVAB / WVR AL SVUB: -50 °C to +110 °C

GEA AWP GmbH

Armaturenstr. 2

17291 Prenzlau

Germany

Phone: +49 3984 8559-0

Fax: +49 3984 8559-18

As part of the global operating GEA group, GEA AWP is the specialist for the development and manufacture of valves and components used in industrial heating and refrigeration plants and machinery. The company is based in the town of Prenzlau, located near Berlin and employs about 100 employees.

GEA AWP GmbH

Armaturenstr. 2

17291 Prenzlau

Germany